Glass wool felt

Still hesitating? Get the samples first,Contact us!

Classification

Keywords

- Product Description

-

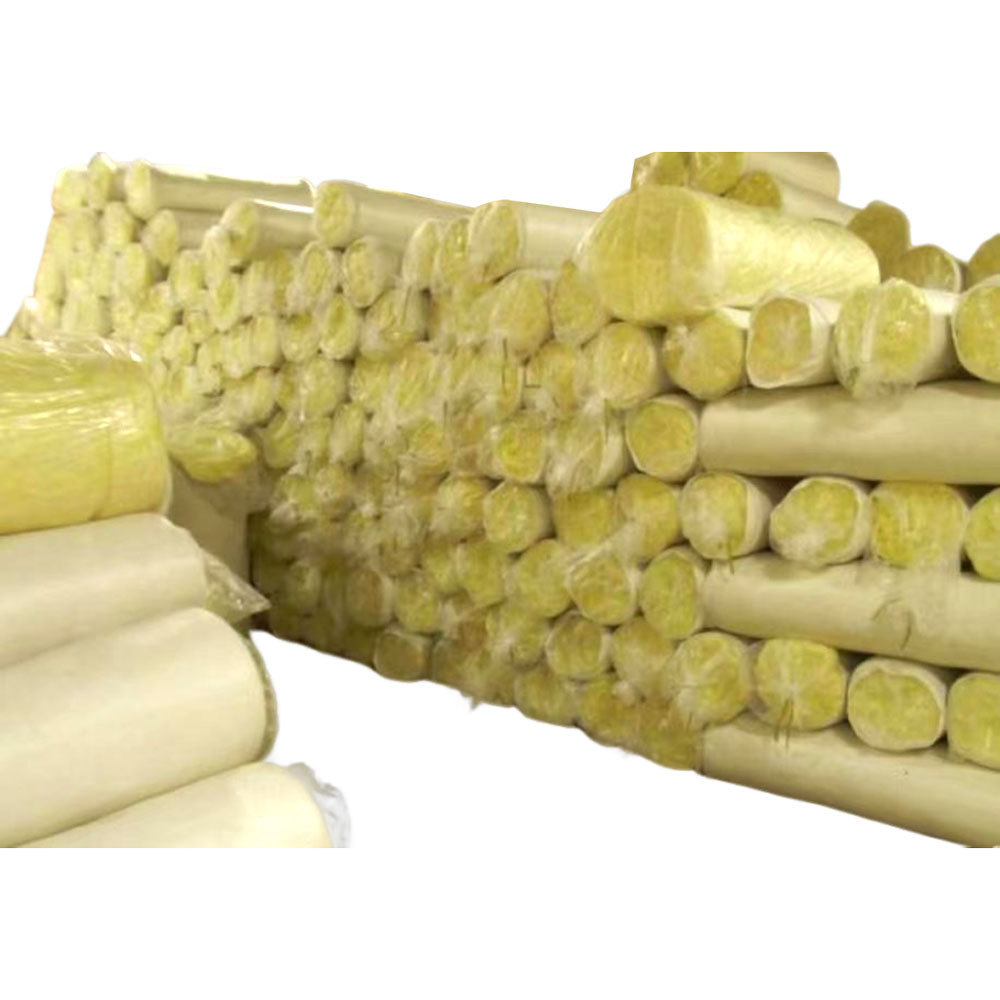

Rock wool felt is to adapt to the large area of laying needs and made of coiled material, in addition to maintaining the characteristics of thermal insulation, but also has excellent shock absorption, sound absorption characteristics, especially for low frequency and all kinds of vibration noise have good absorption effect, help to reduce noise pollution, improve the working environment. This material in the construction can also be arbitrarily cut according to the need, mainly used for building indoor, muffler system, transportation, refrigeration equipment, household appliances shock absorption, sound absorption, noise reduction treatment, the effect is very ideal. The rock wool felt with aluminum foil veneer also has strong heat radiation resistance. It is an excellent lining material for high temperature workshop, control room, inner wall of machine room, compartment and flat top.

Rock wool felt is one of the main members of rock wool products, mainly used in insulation building materials. The production process of rock wool uses natural rock, ore, etc. as raw materials, melted in a cupola furnace or other pool kiln (temperature below 2000 ℃), and blown and quenched into fibrous cotton with a pressure of 50 atmospheres. These inorganic mineral fiber itself is not flammable, but in the actual process of processing into products, need to add organic binder or additives and other substances, these substances make rock wool board, rock wool and other rock wool products with combustion. In addition, the amount of combustible adhesive added in the production process directly affects the combustion performance of rock wool products, and the amount of combustible adhesive can be determined according to the use of the product during the production process.

Glass wool felt

Still hesitating? Get the samples first,Contact us!

Product classification

Keywords

INQUIRY

Note: Please leave your contact information and our professionals will contact you as soon as possible!

Related Products